Characteristics and development direction of power electronic film capacitors

金属化薄膜电容器(电力电子薄膜电容器)的特点及发展方向

www.dawncap.cn www.dawncapacitors.com

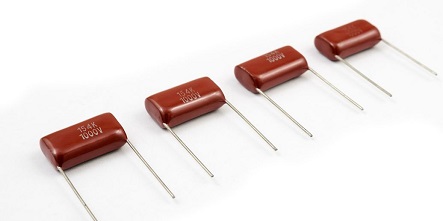

薄膜电容器又称塑料薄膜电容器。它使用塑料薄膜作为电介质。

薄膜电容器常用的制造方法是以铝和其他金属箔为电极,与塑料薄膜重叠后包裹在一起。然而,还有另一种薄膜电容器的制造方法,称为金属膜电容,即真空蒸发塑料膜上的一薄层金属作为电极。这样,可以省略电极箔的厚度,并且可以减小电容器的每单位容量的体积。因此,薄膜电容器易于制成大容量的小电容器。例如,常见的MKP电容器是金属化聚丙烯薄膜电容器的名称,而MKT是金属化聚乙烯电容器的名称。

金属膜电容器中使用的薄膜包括聚乙烯、聚丙烯、聚碳酸酯等。除绕组型外,还有层压型。金属膜电容器具有所谓的自愈作用,即如果电极的一小部分由于脆弱的电气接口而短路,短路部分周围的电极金属会因电容器当时携带的静电能或短路电流导致较大面积的熔化和蒸发而恢复绝缘,再次恢复金属膜电容器的功能。

金属膜电容器是在聚酯膜表面蒸镀一层金属膜,代替金属箔作为电极。由于金属化膜的厚度远小于金属箔的厚度,因此绕组后的体积远小于金属箔电容器的体积。金属膜电容器的很大优点是“自愈”特性。金属膜电容所谓自愈特性是,如果薄膜介质在某一点上有缺陷,在过电压作用下发生击穿短路,击穿点处的金属化层在电弧作用下瞬间熔化蒸发,形成一个小的无金属区,使电容器的两极可以再次绝缘并继续工作,从而大大提高了电容器的可靠性。从原理分析来看,金属化薄膜电容器不应存在短路故障模式,金属箔电容器会出现许多短路故障现象。虽然金属膜电容器具有上述优点,但与金属箔电容器相比,它也有以下两个缺点:

首先,金属膜电容容量稳定性不如箔式电容器,因为金属膜电容器在长期工作条件下容易发生容量损失,自愈后会导致容量降低。因此,如果用在对金属膜电容容量稳定性要求较高的振荡电路中,金属箔电容器应该更好。另一个主要缺点是承受大电流的能力差,这是因为金属膜电容比金属箔薄得多,并且承载大电流的能力弱。为了改善金属膜电容器的缺点,在制造过程中对大电流金属化薄膜电容器产品进行了改进。

金属膜电容器主要应用于电子、家电、通讯、电力、电气化铁路、混合动力汽车、风力发电、太阳能发电等行业。这些行业的稳定发展促进了金属膜电容器市场的增长。

随着科技的发展,电子、家电、通讯等行业的更新周期越来越短。金属膜电容器以其良好的电气性能和高可靠性,成为推动这些产业更新不可缺少的电子元件。未来几年,随着数字化、信息化、网络化建设的进一步发展,国家在电网建设、电气化铁路建设、节能照明、混合动力汽车、消费电子产品升级等方面加大投入,金属膜电容器的市场需求将进一步呈现快速增长的趋势。

据中国电子元器件工业协会统计,预计未来,全球金属膜电容器市场将以15~20%的速度快速增长。金属膜电容器市场的增长将推动聚丙烯电子薄膜市场的快速增长。

Characteristics and development direction of metallized film capacitors (power electronic film capacitors)

Film capacitor is also called plastic film capacitor. It uses plastic film as the dielectric.

The common manufacturing method of thin film capacitor is to use aluminum and other metal foils as electrodes and wrap them together after overlapping with plastic film. However, there is another method for manufacturing thin-film capacitors, called metal film capacitors, that is, vacuum evaporation of a thin layer of metal on the plastic film as an electrode. In this way, the thickness of the electrode foil can be omitted, and the volume per unit capacity of the capacitor can be reduced. Therefore, thin film capacitors are easy to be made into small capacitors with large capacity. For example, the common MKP capacitor is the name of metallized polypropylene film capacitor, while MKT is the name of metallized polyethylene capacitor.

Characteristics and development direction of metallized film capacitors (power electronic film capacitors)

The films used in metal film capacitors include polyethylene, polypropylene, polycarbonate, etc. In addition to the winding type, there are also laminated types. The metal film capacitor has the so-called self-healing effect, that is, if a small part of the electrode is short circuited due to the fragile electrical interface, the electrode metal around the short circuited part will restore the insulation due to the melting and evaporation of a large area caused by the electrostatic energy or short-circuit current carried by the capacitor at that time, and restore the function of the metal film capacitor again.

Metal film capacitor is to evaporate a layer of metal film on the surface of polyester film to replace metal foil as electrode. Since the thickness of the metallized film is much smaller than that of the metal foil, the volume after the winding is much smaller than that of the metal foil capacitor. The great advantage of metal film capacitor is its "self-healing" characteristic. The so-called self-healing characteristic of metal film capacitor is that if the film dielectric has defects at a certain point, breakdown and short circuit will occur under the action of overvoltage, and the metallized layer at the breakdown point will melt and evaporate instantly under the action of arc, forming a small metal free zone, so that the two poles of the capacitor can be insulated again and continue to work, thus greatly improving the reliability of the capacitor. From the principle analysis, metallized film capacitors should not have short-circuit fault mode, and metal foil capacitors will have many short-circuit faults. Although metal film capacitors have the above advantages, compared with metal foil capacitors, they also have the following two disadvantages:

Firstly, the capacity stability of metal film capacitor is not as good as that of foil capacitor, because metal film capacitor is prone to capacity loss under long-term working conditions, and the capacity will be reduced after self-healing. Therefore, the metal foil capacitor should be better if it is used in the oscillation circuit that requires high stability of metal film capacitance.

Another major disadvantage is the poor ability to withstand large current, because the metal film capacitance is much thinner than the metal foil, and the ability to carry large current is weak. In order to improve the disadvantages of metal film capacitors, the high current metallized film capacitors were improved in the manufacturing process. The main improvements are as follows:

Metal film capacitors are mainly used in electronics, home appliances, communications, electric power, electrified railways, hybrid electric vehicles, wind power, solar power and other industries. The steady development of these industries has promoted the growth of metal film capacitor market.

With the development of science and technology, the renewal cycle of electronics, home appliances, communications and other industries is becoming shorter and shorter. Metal film capacitor has become an indispensable electronic component to promote the renewal of these industries because of its good electrical performance and high reliability. In the next few years, with the further development of digitalization, informatization and networking, the state will increase investment in power grid construction, electrified railway construction, energy-saving lighting, hybrid electric vehicles, consumer electronics upgrading, etc., and the market demand for metal film capacitors will further show a trend of rapid growth.

According to the statistics of China electronic components industry association, it is expected that the global metal film capacitor market will grow rapidly by 15~20% in the future. The growth of metal film capacitor market will promote the rapid growth of polypropylene electronic film market.